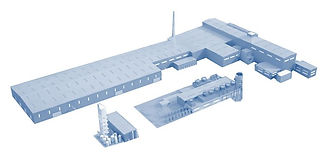

ROLLING MILL

The rolling mill (RM) makes products like: rebars, angular profile, beams, wire rod in coils, rebar in coils. Typically a RM has a range of products that are demanded for its market around. A RM starts from the reheating furnace where steel billets are heated in order to be sent to rolling stands. Every area of RM such as reheating furnace, rolling stands (roughing, intermediate, finishing), shears, thermal treatment line, transporter channels, cooling bed, cold shears, packing area, loading area, have its maximum productivity in tons per hour for each type of product. In order to get highly efficient RM it should be designed as a one complete mechanism. Even more reasonable to combine a melt shop and rolling mill together, that will reduce energy consumption.

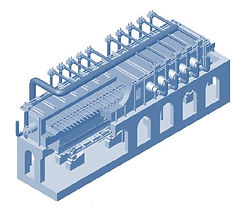

REHEATING FURNACE

Reheating furnace has a function to heat cold billets until predefined temperature by gas flame and prepare them for rolling through the stands. A reheating furnace must have good efficiency, without consuming excess of natural gas and not generating to much scale from the billets.

DSTEEL can provide high performance reheating furnaces: pusher type, walking hearth type, walking beam type, with productivity in the range 20-200 ton per hour.

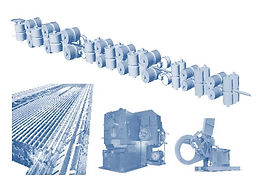

ROLLING LINE

The rolling line for long products includes roughing, intermediate and finishing stands, a number of shears, thermal treatment line, transporter channels, monoblock, laying head, cooling bed, cold sheas, packing areas & different other technological equipment. The important factor of the rolling line is a capability to follow easily the production planning, without loosing extra time on restartings and unpredicted maintenance.

DSTEEL can supply a rolling line for rebars, angular profiles, beams, wire rod in coils, rebar in coils, with productivity in the range from 20 to 200 ton per hour.

AUXILIARY EQUIPMENT

DSTEEL can design and provide for a rolling mill:

bay cranes, water treatment plant (WTP), mechanical work shop of the RM, laboratories for process & quality control, automation systems.