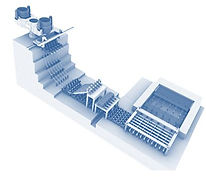

STEEL MAKING

Steel making is being performed in a melt shop, which is always designed according to certain metallurgical process, taking into account all available resources and infrastructure around. Converter or electric arc furnace (EAF) are two general solutions. The first one is to manage the hot metal (pig iron) and the second is for melting the scrap. However, a number of intermediate approaches are also possible. The product that is going out of the melt shop is defined by continuous casting machine (CCM) that can produce billets, blooms, round sections and slabs. Depending on the steel grades, before arriving to CCM the steel in the ladles can go through the treatments on the ladle furnace (LF), vacuum degasser (VD) or vacuum oxygen degasser (VOD). So, a MS is consuming combinations of: scrap, DRI, CBI, hot metal - as a source of steel, and electricity, oxygen, gas, coke, lime, ferro-alloys, cooling water, refractories, as consumable materials. The most important thing to organize correct balance of the things in order to get efficient, safe and ecological way of steel making.

EAF

Electric arc furnace is an equipment for melting of the scrap by graphite electrodes and tapping of the liquid steel. EAF can have different automation options and possibility for future upgrades. DSTEEL can provide high performance EAFs with different volumes in the range from 20 to 150 tons. Custom design is available on request.

LF, VD, VOD

The ladle furnace is a unit that is providing correct chemical composition of the steel according to the requirements of the final products. The main function of LF is to recover valuable alloying elements, desulfurization and ensuring the right temperature to arrive to CCM. Different solutions can be offered depending on the steel grades and steel process. DSTEEL can supply LF, VD, VOD with sizes from 20 to 150 tons.

CCM

DSTEEL can design a CCM for production of billets, blooms, rounds and slabs. The number of strands is according to process. The type of dummy bar to use is defined by evaluation. Withdrawal & straightening machine depends on the products, such as soft reduction for special steels and slabs. Different options are available on request. DSTEEL can provide CCM for: billets 125-150 mm square section, bloomes 160-360 mm, rounds with Ø100-600 mm, slabs 120-350 mm in thickness.

AUXILIARY EQUIPMENT

DSTEEL can design and provide for a melt shop:

Bay cranes, scrap buckets, ladles, ladle cars, de-dusting systems (DDS), water treatment plant (WTP), oxygen plant, laboratories for process & quality control, automation systems.